The production and use of virgin and recycled steel result in unavoidable emissions of carbon dioxide. Less steel means a smaller carbon footprint. However, reality isn’t that simple. It’s not about choosing sustainability over safety; it’s about choosing what’s perfect for you. We’ve done the math in our CO2 emissions calculations.

CALCULATED PROTECTION

As the global leader in steel mesh panel solutions, it’s our responsibility to keep you safe and reduce your carbon footprint. We’re constantly trying to increase the amount of recycled steel in our products, but we’re also helping our customers to make more thoughtful decisions, both for themselves and the environment. Above all, we make it easier to compare products from a broader perspective. In our CO2 emissions calculations, we take both safety and sustainability into consideration.

THIS IS HOW WE DID IT

To make it easier for you as a customer to make informed decisions, Troax uses a structured method to calculate the carbon emissions associated with our products. We calculate our total CO2e emissions annually and divide this by the total weight of products sold over the year. Through this approach, we can assign a specific CO2 value to each product, giving you as a customer a clear picture of the product’s environmental impact.

In our calculations, we do not take into account recycling at the end of the product life cycle, as Troax currently cannot control how our customers handle the products after use. Recycling processes also vary greatly between different markets. We focus on ensuring that our products are designed to be easily recyclable. For example, our panels are 99% recyclable, with the only exception being the panels’ paint. We also encourage the reuse of our products to extend their lifespan.

Emissions related to transportation to our factory in Sweden, capital goods, and leased assets within emission category 3 are excluded.

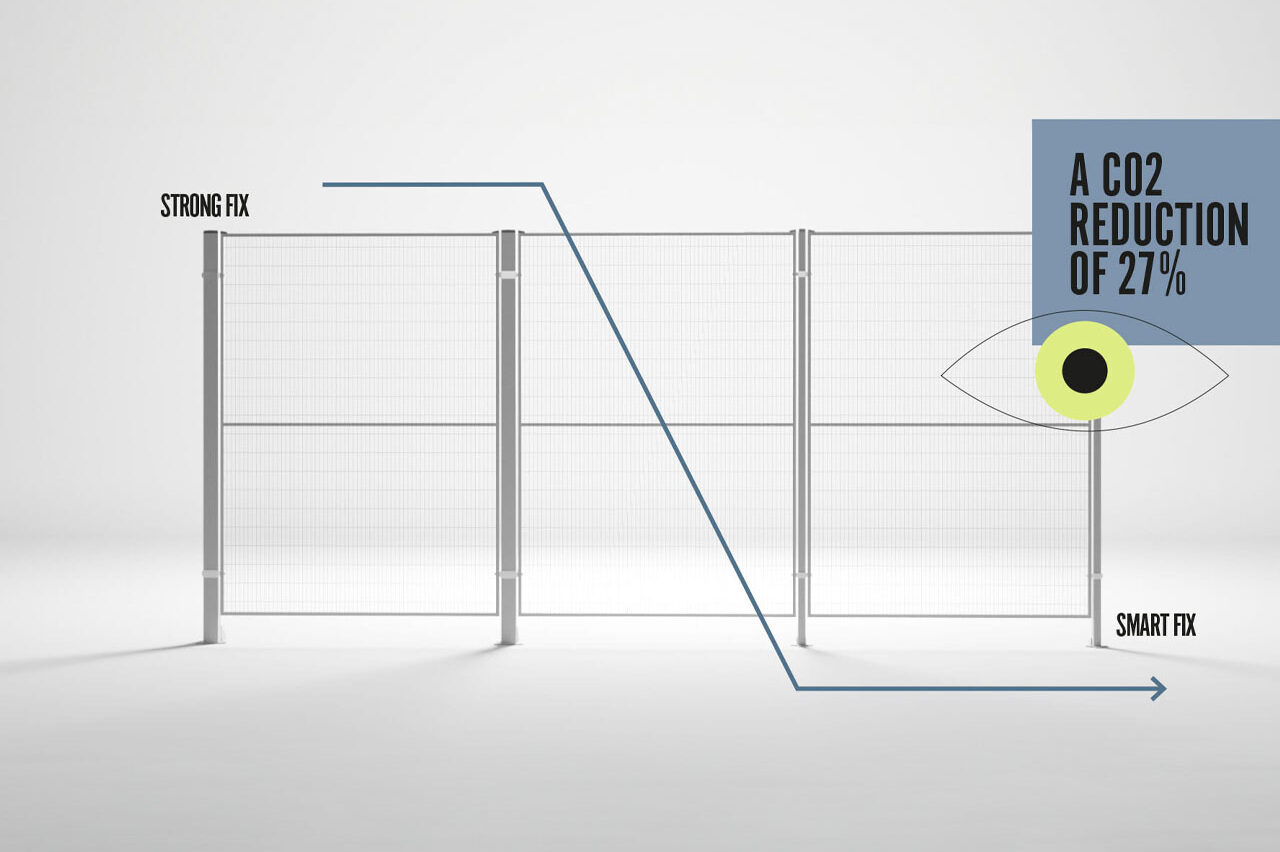

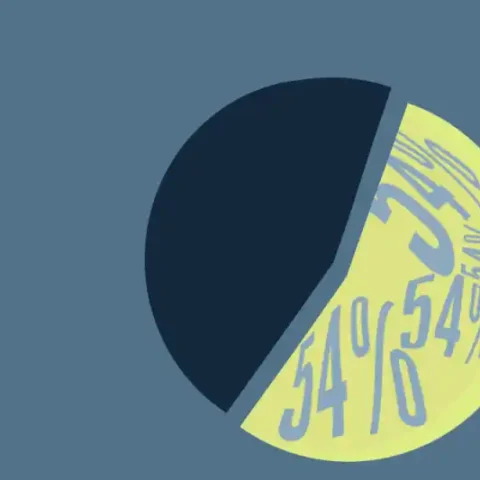

Central throughout our procedure is that we base a lot on weight, this is because 92-94% of our total emissions depend on purchased steel. For example, our lighter 60×40 post, which can withstand up to 2100 joules, can reduce CO2 emissions by 54% compared to our larger 80×80 post that withstands 8180 joules. We want to highlight the difference weight makes if there is no need for high resistance.

15% LESS CO2

Our mesh panel, ST20 2050×1500, has a 15% smaller carbon footprint compared to the stronger ST30 2050X1500.

CUT THE FOOTPRINT BY 54%

The stronger 80x80x2200 post is tested to withstand impacts up to 8,180 joules. A significantly lighter product, like our 60X40X2200 post can withstand 2,100 joules, but it also has a smaller carbon footprint. Due to the lower weight, the difference is 54% in terms of CO2 emissions